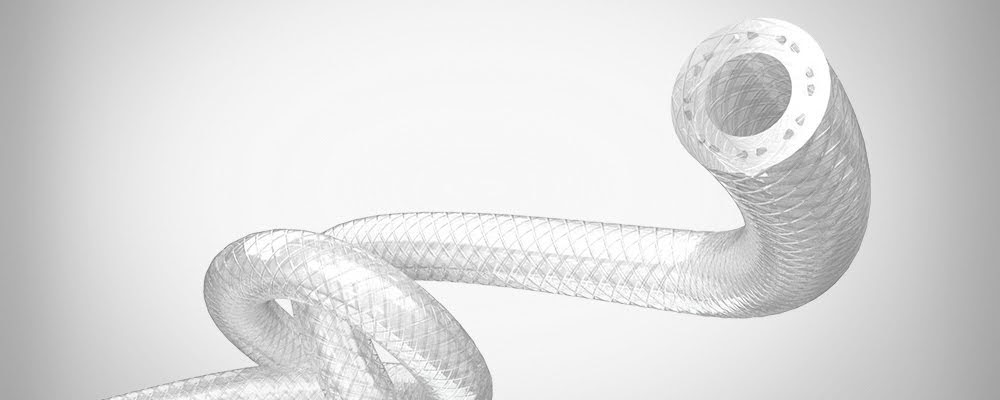

Braiding

We can provide you with braided catheter solutions as a sub-assembly thereby enabling you to benefit from our expertise in braiding technologies.

From braid-on coil, multi-lumen, and stepped shaft catheter systems, we can deliver a custom-made design for your project’s needs.

We offer high-quality braided medical tubing, that can be customized to fit your design needs. We frequently work with flat and round stainless-steel wire in addition to monofilaments. Regardless of your requirements—be it torque control, kink resistance, or column strength, One Medical Extrusion can custom manufacture braided tubing for you.

Shaft Dimensions

- OD range: 2 French (0.0026”, 0.66mm) through 24 French (0.315”, 8.00mm)

- Wall thickness: 0.005” (0.13mm) – 0.038” (0.97mm)

Braid Construction

Types:

- 304 Stainless Steel

- 316 Stainless Steel

- Nylon

- Nitinol

Wire Size:

- Round: 0.001” (0.0025mm) – 0.0004” (0.10mm)

- Flat: 0.0005” X 0.0003” (0.013mm X 0.08mm) – 0.002” X 0.007” (0.05mm X 0.18mm)

Braiding patterns:

- Diamond (2 wires under 2 over 2)

- Herringbone (1 wire under 2 over 2)

- Half Diamond (1 wire under 1 over 1)

Braiding cores:

- Directly onto catheter, PTFE, HDPE

- OD: 0.2mm – 8.00mm

Braid machines, & Wire pattern:

- 16 machines

- 5 – 250 PPI

Over-Coating/Over-Jacketing

Extrusion (Over-Coating of Mandrels/ Over-Jacketing of Hypotubes)

In over-coating/over-jacketing, a core mandrel or hypo-tube (which can be a braided component, profiled mandrel, or hypo-tube) is fed through an extruder to coat a layer of thermoplastic polymer.

Our team can provide coatings as thin as 0.001″, depending on the size of the substrate. We can over-jacket laser cut hypo-tube for balloon catheter applications also. Our team works with numerous materials, including but not limited to Polyurethane, Pebax®, and various Blends.We will work with you to determine the ideal over-coating/over-jacketing material for your unique application.