Through an extensive investment in our value-adding capabilities, our engineers have developed a broad portfolio of tipping, flaring, and other thermal forming capabilities. We are your competent partner for thermal reforming of tubing. A variety of technologies are used, depending on the material. Our strategic investments in a wide array of value-added services have been instrumental in cultivating a deep and comprehensive expertise in thermal forming processes, encompassing specialized techniques such as precise tipping and controlled flaring. Over years of dedicated work, our experienced engineers have built an extensive and diverse portfolio of proven capabilities in this niche field. This wealth of practical knowledge and technical skill firmly positions us as a highly proficient and reliable collaborator for projects requiring the thermal reforming of various types of tubing. We possess a nuanced understanding of material science and employ a diverse range of material-dependent technologies and methodologies, allowing us to tailor our approach to the specific requirements of each project and ensure optimal outcomes. Our commitment to continuous improvement and investment in cutting-edge thermal forming technologies ensures that we remain at the forefront of this specialized area, offering our clients innovative and effective solutions for their tubing modification needs.

Tipping and Flaring Capabilities

Our advanced thermoforming technology offers extensive capabilities for shaping the tips of medical tubing to meet precise customer specifications. We can create a wide array of radial designs, including fully cylindrical, completely closed, and centrally open configurations. These can be produced in various lengths to suit diverse application needs. Furthermore, we offer the option of incorporating inserts, such as titanium balls, to enhance visibility and recognition in critical imaging procedures like CT and MRI scans. The integration of such features ensures accurate placement and monitoring during medical interventions.

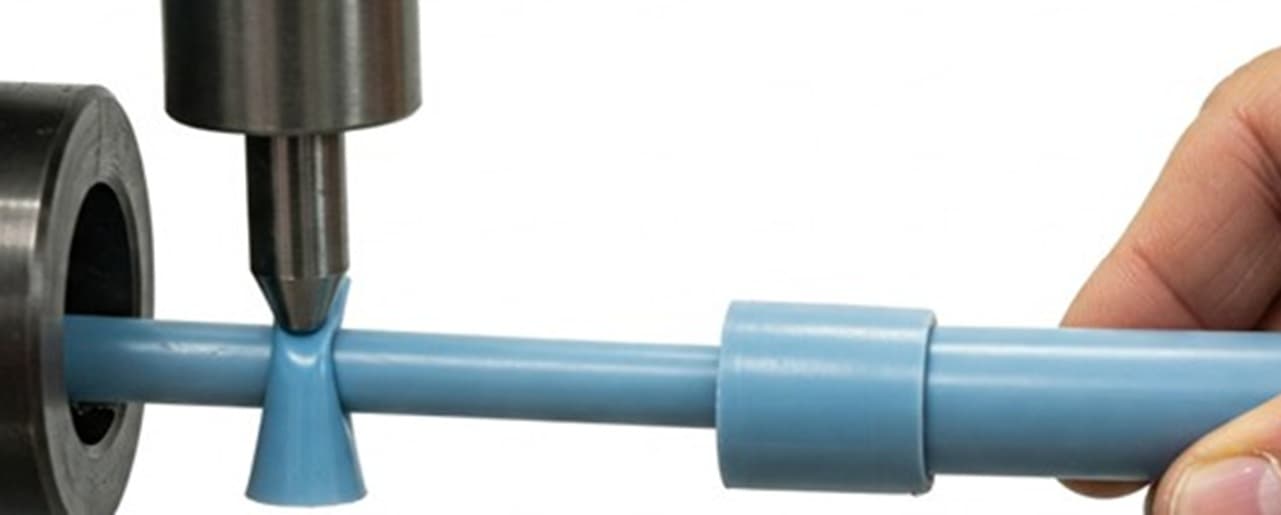

Beyond tip forming, we also specialize in the flaring of flanges, a crucial step for the secure and reliable connection of our tubing to other molded components. This process is carefully tailored to your unique requirements, taking into account the specific design and functional demands of your application. We possess a diverse range of flaring technologies, allowing us to expertly process a variety of thermoplastic materials, ensuring optimal bond strength and long-term performance of the assembled medical device. Our engineering team will work closely with you to determine the most appropriate thermoforming and flaring techniques to achieve your desired product characteristics.

Other Thermal Forming Capabilities

Utilizing thermal forming processes, we possess the capacity to fabricate both planar configurations, exemplified by helical structures, and volumetric geometries, such as coiled formations. These products can be manufactured with a diverse range of dimensions and configurations.

Contact us to learn more about how our thermal forming capabilities can benefit your medical device applications.